Tahoe Boats Learning Center

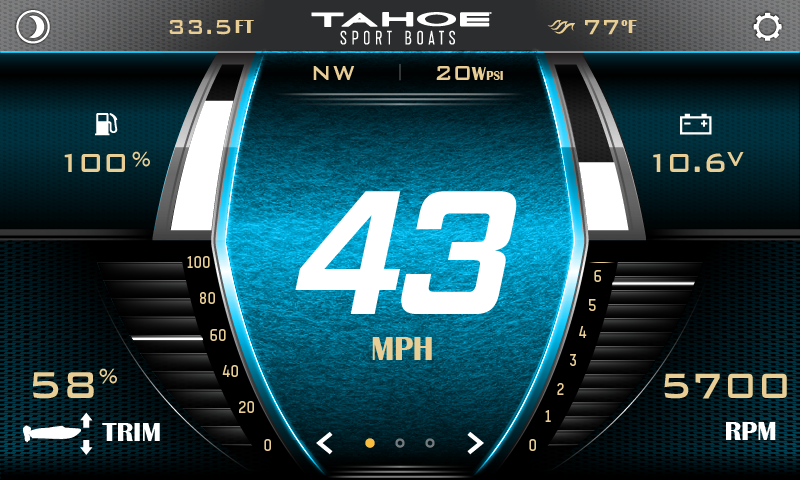

Digital Display Dashboard

Introducing an all-new Digital Display Dashboard on select TAHOE Boat models. An interactive touchscreen that puts more control and information at your fingertips.

Boat Financing Basics

Building a plan for financing is a great step to minimize uncertainty while you shop for boats. Learn about the basics of boat financing and the resources available to help you stay stress-free as you buy your boat.

Boat Accessories

From fishing to watersports to lounging, TAHOE® boats are available with a variety of accessories to help enhance your outings.

Custom Trailers

There’s a good chance your TAHOE® will spend quite a bit of time on its trailer, which is fine because we build our trailers to perfectly match the boats riding on them.

Inboard Motor Installation

TAHOE® is a certified installer through the Mercury Marine Installation Quality Certification Program, an important credential in delivering top tier performance and owner satisfaction in sterndrive boats.

CSI Award

TAHOE® Boats is honored to receive the 2019 NMMA CSI Award for Customer Satisfaction in Fiberglass Outboard Boats and Deck Boats.

Motor Power Options

Sterndrive or outboard? What’s the difference and why does it matter? Find out which motor choice would work best for your TAHOE® needs.

Boat Covers

Whether you want to protect your TAHOE® boat on the trailer at home or your crew on the water, we offer a variety of quality covers to fit your every need.